As we weren’t able to officially open our Smiddy on Wednesday 1 April, here is a sneak preview of what you will be able to see when the Museum can open again…….

Baldow Smiddy, Kincraig, was originally a wooden building, closed in 1929 and moved into a converted stone cottage next door. The Smiddy continued to serve the community into the 1990s when the last blacksmith retired. We have reproduced the original building using timbers from the stone cottage and our own timber from our pinewoods.

The Smiddy acted as the “hub” of village life and local news and gossip was exchanged between the blacksmith and his customers. The blacksmith made or repaired many every-day household items, as well as forging farming tools and shoeing horses. During the twentieth century, motor vehicles gradually took the place of horses and the role of the blacksmith changed completely, with many using their skills to become engineers. It was common for a Garage to grow out of a blacksmith’s workshop and those businesses flourished as the Smiddy declined.

This Smiddy is interpreted for the 1920s, reflecting the move to the Garage next door, while still functioning as a traditional forge.

Horse shoe nails were bought by the box in a variety of sizes – these are 2¾ inches in length and the weight of the box is 25lbs (11 kg). A stock of horse shoes were often made up by the blacksmith for his customers – each horse having its own set, made to fit. In an old blacksmith’s workshop there would be a number of horses’ names written on a roof beam, with the horse shoes hung underneath each name. If a horse died, its shoes would often be left in place for years afterwards.

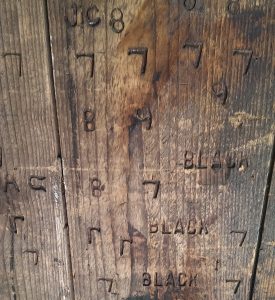

When heating up a branding iron to mark boxes or tools, the smith would test it first on a convenient piece of wood. There are several numbers on this cupboard, including the name “Black”.

On the wall is a lever-worked punch for putting square holes into hot horse shoes. The square holes take the square shanks of “sharps”, also called “cogs” that were put into the shoes to give the horse more grip. The “sharps” or “cogs” were chisel pointed for work in icy conditions.

With the generous support of: